Kim jesteśmy?

OBEJRZYJ NASZE WIDEO

Nasi klienci

Kontakt

JAK MOŻEMY POMÓC?

Adres korespondencyjny

Adres rejestrowy

tel.: +48 517 100 084 | biuro@robotrendy.pl

Centra obróbcze CNC to jedne z najczęściej robotyzowanych maszyn produkcyjnych w zakładach przemysłowych…

Dynamiczny rozwój przemysłu formowania wtryskowego stawia przed firmami coraz wyższe wymagania…

Zastosowanie robotów przemysłowych

w procesie frezowania, polerowania, czy gratowania jest coraz częściej stosowane…

Nasza firma posiada bogate doświadczenie w realizacji projektów z zakresu nakładania powłok kompozytowych m.in…

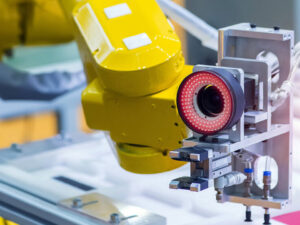

Systemy

wizyjne

Lokalizacja detalu w przestrzeni jest niezbędną informacją wymaganą do robotyzacji danego procesu…

Nasze doświadczenie zebrane podczas wdrożeń automatyzacji i robotyzacji pozwala nam na oferowanie wsparcia…

OBEJRZYJ NASZE WIDEO

JAK MOŻEMY POMÓC?

Adres korespondencyjny

Robotrendy Sp. z o.o.

ul. Modlińska 246A

03-152 Warszawa

+48 517 100 084

Adres rejestrowy

Robotrendy Sp. z o.o.

ul. Brata Alberta 43A

05-075, Warszawa-Wesoła

NIP 9522137464